Hydraulic systems are used in a wide variety of industries, from manufacturing to construction to transportation.

These systems rely on a complex set of components to operate efficiently and reliably, and choosing the right hydraulic system components manufacturer is essential to ensuring that your system runs smoothly.

In this article, we will discuss some key factors to consider when choosing a hydraulic system components manufacturer.

Factors to Consider When Choosing a Hydraulic System Components Manufacturer

- Quality and Durability: When it comes to hydraulic systems, quality and durability are critical. Look for a manufacturer that uses high-quality materials and has a reputation for producing reliable components that can withstand the demands of your specific application.

- Range of Products: Different hydraulic systems require different components, so it is important to choose a manufacturer that offers a wide range of products to meet your needs. Look for a manufacturer that offers components such as pumps, valves, cylinders, hoses, and fittings, as well as more specialized components for specific applications.

- Technical Expertise: Hydraulic systems can be complex, and it is important to choose a manufacturer that has the technical expertise to help you choose the right components for your needs. Look for a manufacturer that employs knowledgeable engineers and technicians who can help you design and implement a hydraulic system that meets your specific requirements.

- Customization: Depending on your specific application, you may require custom hydraulic system components. Look for a manufacturer that offers customization services to ensure that you get the exact components you need to optimize your system’s performance.

- Service and Support: Even the highest-quality hydraulic system components may require maintenance or repair over time. Look for a manufacturer that offers comprehensive service and support, including technical assistance, troubleshooting, and repair services.

Benefits of Working with a Hydraulic System Components Manufacturer

- Quality and Reliability: By working with a reputable hydraulic system components manufacturer, you can be assured that you are getting high-quality, reliable components that will perform as expected.

- Expertise: Hydraulic systems can be complex, and working with a manufacturer that has a team of experts can help ensure that you get the right components for your specific application.

- Customization: By working with a manufacturer that offers customization services, you can get components that are tailored to your specific needs, helping to optimize your system’s performance.

- Efficiency: Using high-quality hydraulic system components can help improve your system’s efficiency, resulting in lower operating costs and improved performance.

- Service and Support: Working with a manufacturer that offers comprehensive service and support can help ensure that your hydraulic system components continue to perform at their best over the long term, minimizing downtime and maintenance costs.

Conclusion

Choosing the right hydraulic system components manufacturer is essential to ensuring that your hydraulic system operates efficiently and reliably.

When selecting a manufacturer, consider factors such as quality and durability, range of products, technical expertise, customization, and service and support.

By working with a reputable manufacturer, you can benefit from high-quality, reliable components that are tailored to your specific needs, as well as comprehensive service and support to ensure that your system continues to perform at its best over the long term.

FAQ

What companies make hydraulics?

There are many companies that manufacture hydraulics for a wide range of industries and applications. Here are some examples of companies that make hydraulics:

- Parker Hannifin Corporation: Parker Hannifin is a leading manufacturer of hydraulic components and systems, including pumps, valves, cylinders, and motors.

- Eaton Corporation: Eaton is a multinational company that produces a range of hydraulic products, including pumps, motors, valves, and filters, for various industries such as agriculture, construction, and mining.

- Bosch Rexroth AG: Bosch Rexroth is a German company that produces hydraulic components and systems for industrial and mobile applications, including pumps, motors, valves, and cylinders.

- Danfoss Power Solutions: Danfoss Power Solutions is a global company that produces hydraulic components and systems for various industries, including agriculture, construction, and marine, among others.

- Hydac International GmbH: Hydac is a German company that produces hydraulic components and systems for various applications, including filtration, cooling, and fluid conditioning.

- Caterpillar Inc.: Caterpillar is a well-known manufacturer of heavy equipment and machinery for various industries, including construction, mining, and forestry, and they produce a range of hydraulic components and systems for their equipment.

These are just a few examples of companies that manufacture hydraulics. There are many other companies that produce hydraulic components and systems for various industries and applications.

What are the 5 basic components of a hydraulic system?

The five basic components of a hydraulic system are:

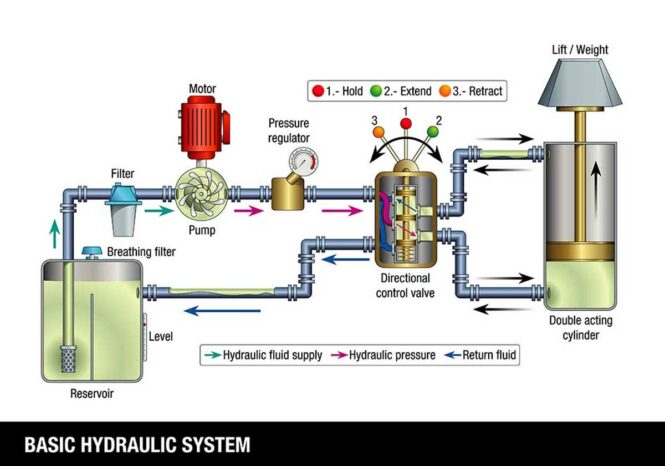

- Reservoir: A hydraulic system requires a reservoir or tank to hold the hydraulic fluid. The reservoir must be properly sized to provide adequate fluid storage and cooling capacity.

- Pump: The hydraulic pump is responsible for pressurizing the hydraulic fluid and delivering it to the rest of the system. The pump can be powered by an electric motor, an internal combustion engine, or another source of power.

- Control valve: The control valve regulates the flow and pressure of hydraulic fluid within the system. It directs the flow of hydraulic fluid to the desired actuator or system component.

- Actuator: The actuator is the component that converts hydraulic pressure into mechanical force. Examples of actuators include hydraulic cylinders, hydraulic motors, and hydraulic presses.

- Hydraulic fluid: Hydraulic fluid is the medium that transmits power within the hydraulic system. It must have the appropriate viscosity, temperature range, and chemical properties to ensure proper system operation.

By combining these five basic components in different ways, hydraulic systems can be designed to perform a wide range of tasks and functions.

What are the 4 main components of hydraulic systems?

The four main components of a hydraulic system are:

- Hydraulic fluid: Hydraulic fluid is the medium that transmits power within the hydraulic system. It must have the appropriate viscosity, temperature range, and chemical properties to ensure proper system operation.

- Pump: The hydraulic pump is responsible for pressurizing the hydraulic fluid and delivering it to the rest of the system. The pump can be powered by an electric motor, an internal combustion engine, or another source of power.

- Actuator: The actuator is the component that converts hydraulic pressure into mechanical force. Examples of actuators include hydraulic cylinders, hydraulic motors, and hydraulic presses.

- Control valve: The control valve regulates the flow and pressure of hydraulic fluid within the system. It directs the flow of hydraulic fluid to the desired actuator or system component.

These four components work together to create a complete hydraulic system. The hydraulic fluid is pressurized by the pump and then directed to the actuator through the control valve. The actuator then converts the hydraulic pressure into mechanical force, which is used to perform a specific task or function.